It’s time for bold leadership in reducing GHG emissions.

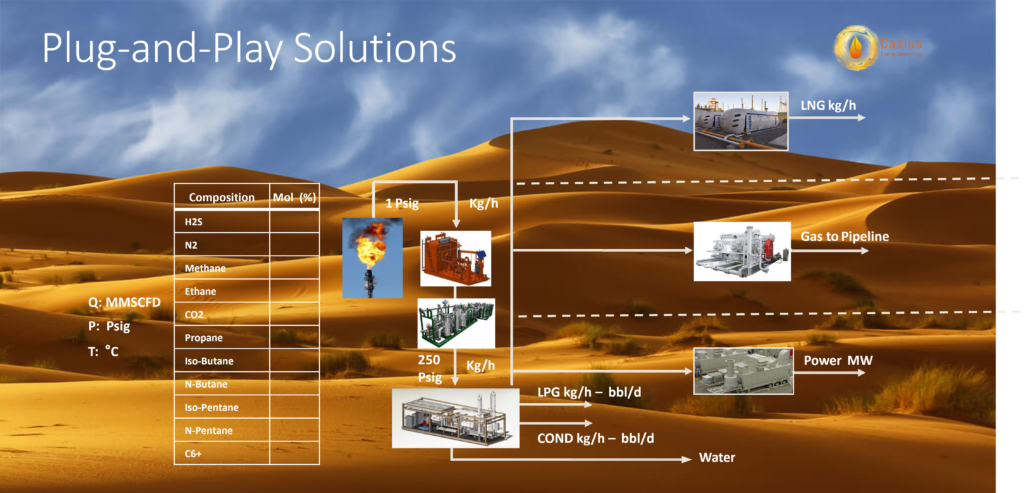

Plug-and-Play-Solution

The question is, how can we move quickly from deliberation to action to decarbonize the industry?

At CASIUS we help Customers turn Liability into VALUE, our value proposition focuses on three niches, drastically reducing emissions and creating products.

First, beginning during the extended well testing or flowback operations, the customer would benefit from monetizing the gas instead flaring during extended periods of operations.

Second, stranded gas wells awaiting facilities, either facilities capacity or flow line or whatever is related to infrastructure, the customer would benefit from accelerating production to generate cash flow.

Third, it is the routine flaring in production facilities, so the customer would benefit reducing the greenhouse gas emissions through quick-win solutions.

How will we do it?

By designing plug-and-play-solutions, based on proven technologies, mobile, portable, and scalable that reduce footprint areas and shorten execution time.

The process scheme begins with a gas composition given by the Customers, raw gas enters the system at a low pressure, then the booster compressor increase pressure till around 250 psi.

Then, the removal of impurities like H2S or CO2 is required, which is generally carried out using technologies based on their adsorption on solid sorbents.

The stream passes through a Compact Unit, which is containerized on skids, passes through two stages of mechanical refrigeration, progressively cooling the gas down to -30 ° C, condensing the heavier hydrocarbons and water.

Three phase separators are used to separate the water, gas, and condensed hydrocarbons. The water is output from the system for disposal by the customer.

A stripping column and reboiler are used to stabilize the condensed hydrocarbons, driving off higher vapor pressure components (methane, ethane) while retaining as much of the C3+ components as possible.

The stabilized liquids are directed to a distillation column which makes use of a reboiler and an air-cooled condensing unit. The resultant outputs then are market spec LPG and stabilized C5+ condensate (may be blended with crude).

Excess propane may also be removed in this step if desired, depending upon the market requirements of the LPG (some markets require LPG to be butane dominated, others do not). The methane & ethane stream is output from the system as conditioned gas, suitable for further processing like LNG or use in power generation or compress into the pipeline.

Gas to Power

Gas-to-power produced from gas flared or stranded wells play an important role in the energy transition landscape.

CASIUS and partnership with international supplier of Gas-to-Power technology to deploy integrated solutions, small or large scale, modular and scalable, either in production facilities or at the wellhead.

Data gathered from mid-to-large producers show a range of expected loads:

- Well pad: 0.25 MW to 2.5 MW

- Central processing facility: 15 MW to 35 MW

- Water handling: 0.5 MW to 10 MW

- E-frac: 25 MW

- Gas processing plant: 5 MW to 15 MW

The benefit of investing in electrical upgrades and/or converting from inefficient, diesel or field gas motors and generators to electrically driven systems substantially reduce GHG emissions and increase energy efficiency.

- Selling Power back to the local grid (if its nearby).

- Displacing Diesel consumption.

- Producers noted improved uptime resulting in the ability to consistently meet daily and monthly production targets.

- Customer’s social license to operate.

Commercial Models

The greatest value and success is achieved when alignment between the Customer, consulting or service provider have a common goal by making everything much more efficient.

Flexible commercial models are offered and the most preferable is Service Model.