Carbon Capture Technologies

The key role of Net-negative GHG emissions technologies in achieving net zero emissions is enlightened in the United Nations Environment Program (UNEP) Emissions Gap Report published in October 2021.

Carbon Removal Technologies

Technologies for the direct removal of carbon dioxide (CO2) from the atmosphere, commonly known as “direct air capture” (DAC), have evolved and successfully outgrown field pilots.

Let’s look at the leading carbon capture companies in operation today

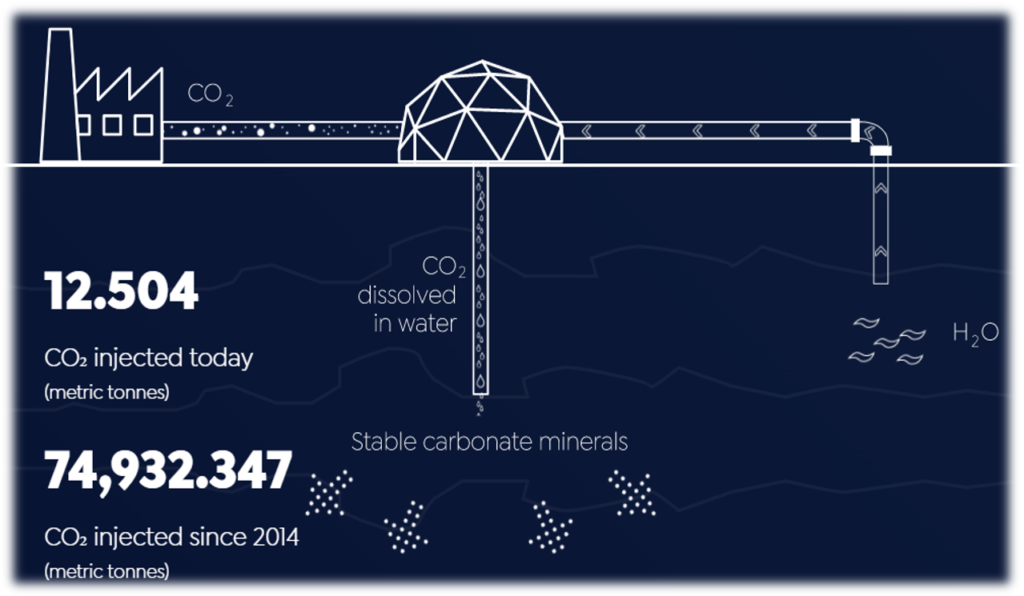

1. Carbfix

- Reykjavik, Iceland.

- 2012-2014 Pilot Project.

- Carbon is dissolved in water and injected underground, into naturally occurring reactive rock formations of suitable composition (basalt). Here, the carbon reacts with elements that are naturally present to form stable minerals

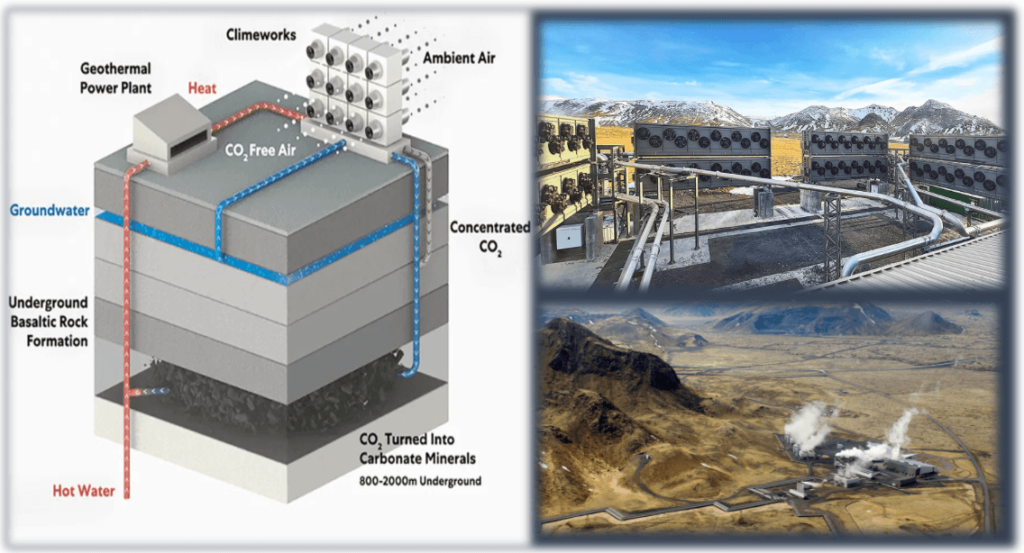

2. Climeworks

- Zurich, Switzerland.

- 2017 Pilot Project.

- Uses modular CO2 collectors that capture carbon dioxide directly from the air to remove unavoidable CO2 emissions, as well as historic CO₂ emissions.

- Use a two-step process, where the air is drawn into the collector by a fan, where it is collected on the surface of a special filter material that is inside the collector.

- The next step takes place when the filter is full and the collector closes. Once it is closed, the temperature is raised to 80-100C, which releases the carbon. It is then collected in its pure and highly concentrated form, ready to be piped away for re-use or underground storage.

3. Global Thermostat

- New York, USA.

- Proof of Concept 2010.

- GT uses custom equipment and proprietary (dry) amine-based chemical “sorbents” that are bonded to porous, honeycomb ceramic “monoliths” which act together as carbon sponges. These carbon sponges efficiently adsorb CO2 directly from the atmosphere, smokestacks, or a combination of both. The captured CO2 is then stripped off and collected using low-temperature steam (85-100° C).

- The output results in 98% pure CO2 at standard temperature and pressure. During the process only steam and electricity are consumed, without the creation of emissions or other effluents.

- This entire process is mild, safe, and carbon negative.

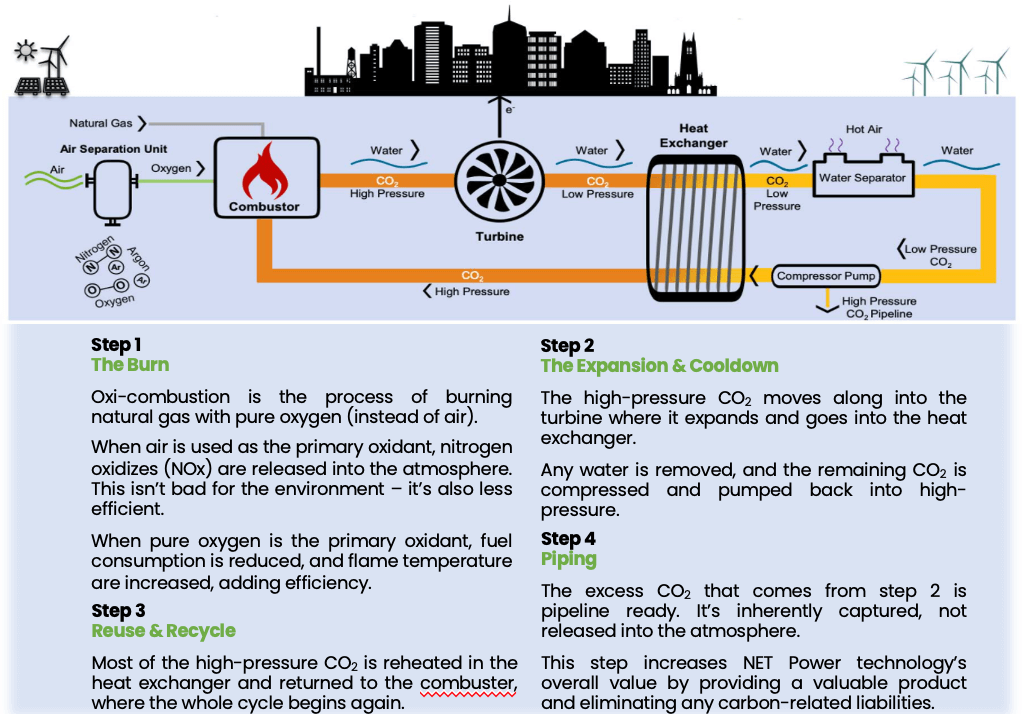

4. Net Power

- Durham, North Carolina, USA.

- First fire 2018.

- NET Power’s electricity is generated by burning natural gas in the presence of pure oxygen, rather than air. This is more efficient and eliminates nitrogen oxide (NOX) emissions from the process.

- The carbon that is released from the burning of the natural gas is then recycled through a series of steps that heat, cool, and compress it to result in low-cost and emission-free electricity. Carbon can then be recycled back into the plant for use and excess can be piped away for re-use by other industries.

- This adds financial incentive to use the method, in addition to the inherent low-cost production model.

5. Carbon Engineering

- Squamish, British Colombia, Canada.

- Pilot demonstration of Direct Air Capture 2015.

- CE uses an air contactor, where the air is pulled in by a huge fan and passes over thin plastic structures that are coated in a potassium hydroxide solution.

- This solution removes carbon from the air and binds the carbon into a liquid solution, where it remains as a carbonate salt. The air is then released, minus the carbon.

- The solution containing the carbonate salt is then run through a series of chemical processes that purify it, concentrate it, and compress it.

- Carbonate salts are separated from the solution into pellets, which are then heated in a calciner to release a pure carbon gas that can be reused or stored underground.

- The remaining pellets are then hydrated and recycled back into the system to make the original capture chemica.

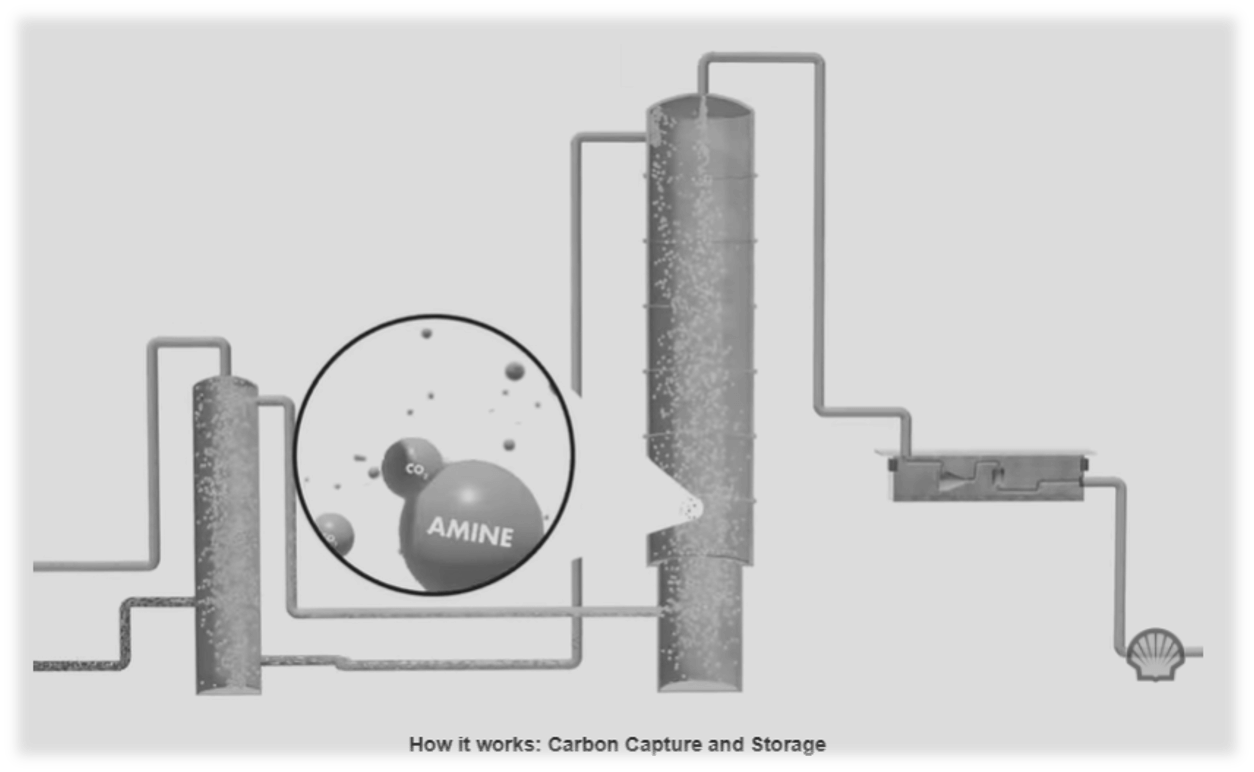

6. Quest Carbon Capture and Storage by Shell

- Edmonton, Alberta, Canada.

- Established 2015.

- Quest’s technology is simple and uses an amine to absorb carbon. The carbon is then separated from the amine and compressed. This turns the CO2 gas into a liquid, which is then piped away to be injected into porous underground rock formations.

- The liquid CO2 is piped 65km away from the plant through various well sites and then injected over 2km underground, unto suitable porous rock formations. Here, it will remain for thousands of years and is considered a permanent solution.

7. CO2 Solutions by Saipem

- Quebec , Canada.

- Pilot Demonstration 2015 – 2017.

- CO2 Solution’s carbon capture process uses a patented “industrial form of carbonic anhydrase, a natural enzyme that enables respiratory carbon management in all living organisms”.

- Their technology allows for carbon to be captured from installations or sites that produce it as a waste product and then re-used or converted in the industries that need it.

- Operations that need carbon to operate but also produce carbon emissions can use the technology to capture their own emissions and then re-use the carbon, which eliminates their greenhouse gas emissions and saves money in the process. The technology is efficient, economical, and produces no toxic waste or emissions.

Unprecedented Momentum

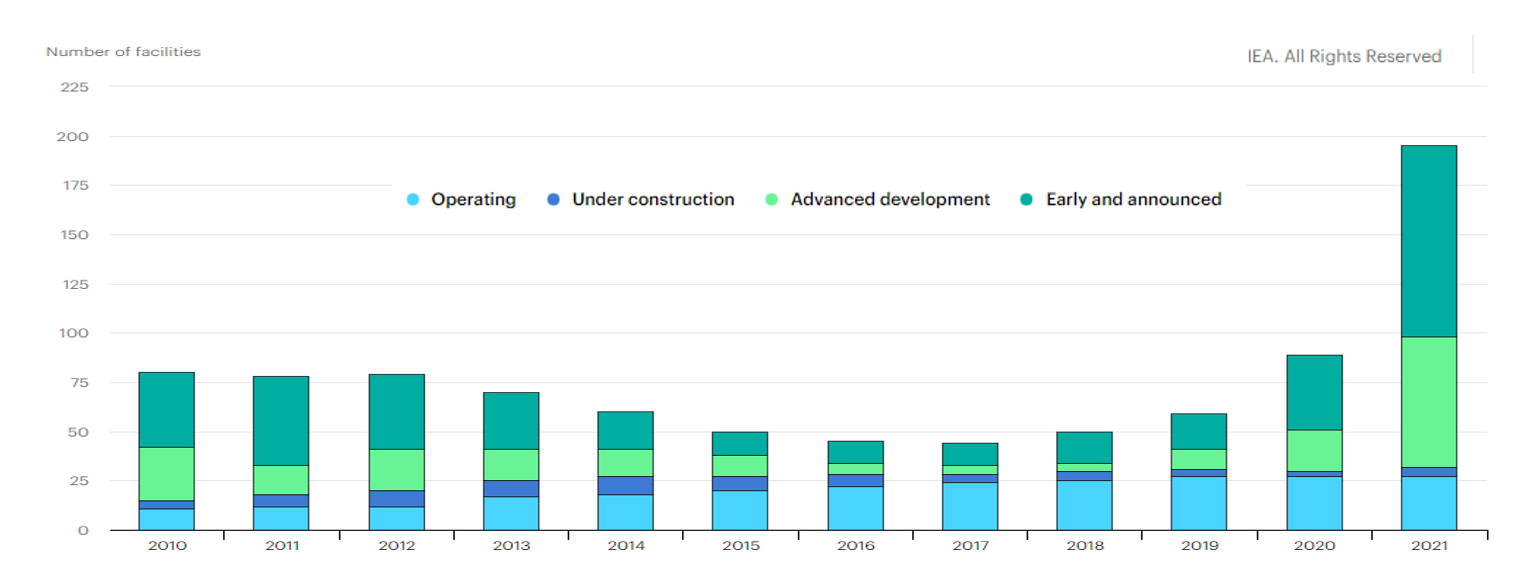

Global pipeline of commercial CCUS facilities operating and in development, 2010-2021

- Carbon Capture and Storage is a viable and essential solution to combat historical emissions and to meet global climate targets.

- Carbon capture is perceived as the way to achieve deep decarbonization in the industrial sector.